Portfolio | Submitted by: Jeremy Keith

Designed by: Josh Elgan

Installers: Jeremy Keith, Jarrod Faul, Jose Belman, Marcelo Ledesma, Maui Ledesma, Senobio Saldivar

Large Scale Guard Railing Enhances Vernon, CA Facility

Elevated Equipment Supply | Vernon, CA

OPTIMIZING COMMERCIAL CULTIVATION WAREHOUSE

Project Overview:

Located in Vernon, CA - In an effort to optimize their warehouse operations and create a safer working environment, Elevated Equipment Supply (EES) partnered with C&SS, a leading provider of innovative storage solutions. The collaboration resulted in the successful installation of Pallet Racking, Shelving, Wire Lockers, and Large-Scale Guard Rails, significantly transforming the way EES manages its inventory and enhances workplace safety.

CUSTOMER DESCRIPTION

Tailored Storage Solution

Eager to revamp their warehouse, EES partnered with C&SS to develop a tailored storage solution that addressed their unique needs and challenges. The proposed plan included the implementation of Pallet Racking, Shelving, Wire Lockers, Large-Scale Guard Rails, etc.

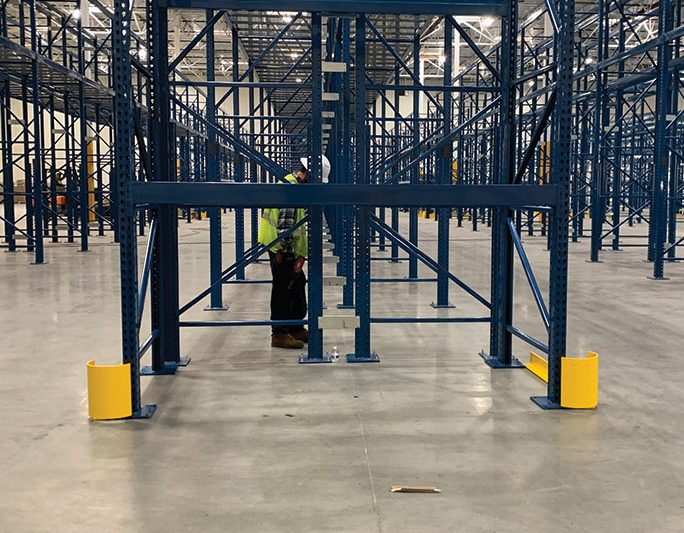

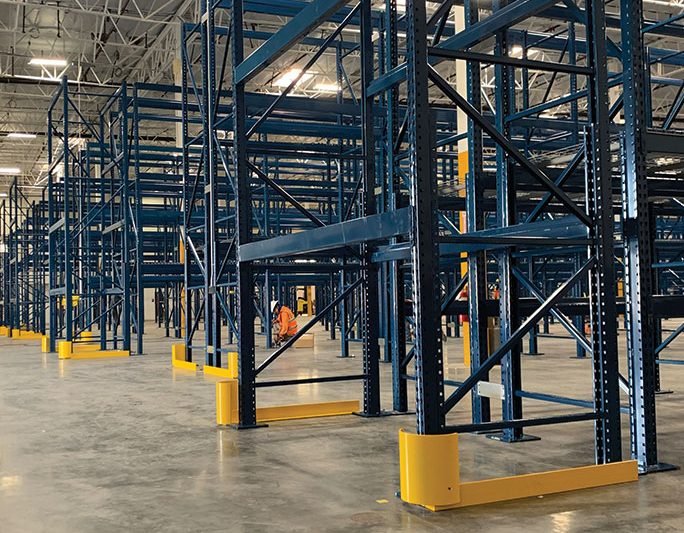

C&SS Team Leader Jose Belman assisted in designing and installation of selective Pallet Racking system to capitalize on the vertical storage space. This smart solution allowed EES to stack palletized goods efficiently, maximizing their storage capacity while maintaining easy access to products. By utilizing the vertical height of their warehouse, EES was able to free up valuable floor space and streamline their inventory management processes.

To handle smaller items and improve organization, C&SS introduced heavy-duty Shelving Units throughout the warehouse. With clear planning and strategic placement, EES employees could now find items quickly, reducing the time spent on inventory searches and ultimately boosting overall productivity.

To enhance security and keep valuable items safe, C&SS installed Wire Lockers within the warehouse. The mesh design of these lockers allowed for visibility of the contents, eliminating the need for constant opening and closing. EES could now store sensitive equipment with confidence, knowing their items were protected without sacrificing accessibility.

Safety was of the upmost importance in this transformation process. C&SS expertly installed Large Scale Guard Rails around the entire warehouse facility storage area and loading docks. These sturdy guard rails acted as a protective barrier, preventing accidents, and minimizing potential hazards. With safety measures in place, EES could maintain a secure and worry-free environment for its employees.

PROJECT SCOPE OF WORK

Efficiency And Professionalism

The implementation of the storage solutions was a well-coordinated effort between EES and C&SS. The teams worked together to minimize disruption to EES's daily operations while ensuring the smooth installation of Pallet Racking, Shelving, Wire Lockers, and Large-Scale Guard Rails. The project was completed within the agreed timeline, with minimal downtime, showcasing the efficiency and professionalism of C&SS.

Elevated Equipment Supply's partnership with C&SS resulted in a warehouse transformation that not only optimized their storage capacity but also prioritized workplace safety. By installing Pallet Racking, Shelving, Wire Lockers, and Large-Scale Guard Rails, EES demonstrated its commitment to efficiency and employee well-being. As the company looks to the future, they are well-equipped to meet customer demands, ensure prompt order fulfillment, and maintain a secure and productive warehouse environment.

OUTCOMES

Secure And Productive Warehouse Environment

The collaboration between EES and C&SS yielded remarkable results, benefiting the company in several ways:

• Optimized Warehouse Space: The Pallet Racking system allowed EES to utilize vertical space effectively, increasing their storage capacity and freeing up valuable floor area.

• Streamlined Inventory Management: With a well-organized shelving system and easy-to-access Wire Lockers, employees could locate items swiftly, reducing order processing time and increasing overall efficiency.

• Improved Workplace Safety: The installation of Large-Scale Guard Rails contributed to a safer warehouse environment, reducing the risk of accidents, and protecting both employees and valuable inventory.

• Enhanced Employee Satisfaction: The smart storage solutions not only boosted productivity but also improved employee morale. A safer and organized workplace led to happier and more motivated staff.